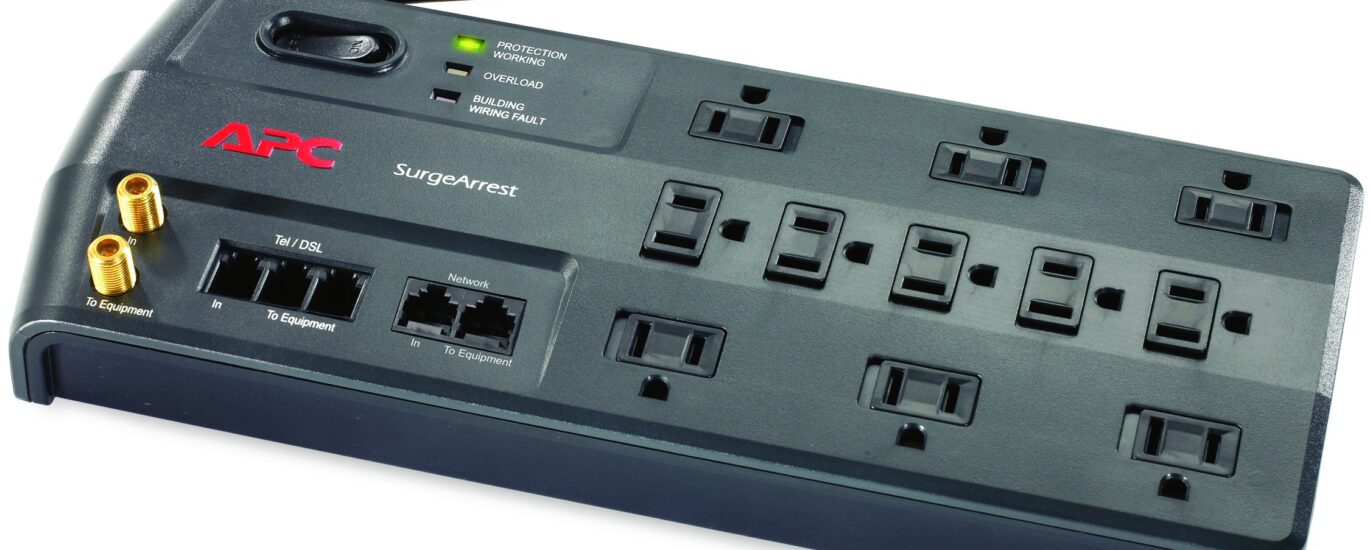

Industrial surge protection devices have grown in popularity and applicability over the years. While these devices may require a large investment to implement, they are an excellent choice for any industrial or commercial space. Companies like Schneider Electric are major players in the electrical protection market. Read on to learn more about industrial surge protection. These devices are crucial for many reasons. Here’s a brief overview of the most popular types. Regardless of their purpose, these surge protectors protect equipment against power surges that can damage or destroy electronics.

There are many types of surge protection devices available, each with its own strong and weak points. The first six methods, for example, use solid-state devices called metal oxide varistor (MOVs) that divert unwanted surge energy to the earth. The last two methods, however, block the energy that strikes the protected load by providing an alternate path to ground. Fortunately, each has its own pros and cons. Ultimately, choosing the best type for your environment depends on how much protection you need.

The most common source of electrical surges is lightning. However, they can also originate from normal utility switching operations or from the unintentional grounding of electrical conductors. Similarly, telecommunications and internet cables can carry surges into a building. Only about twenty percent of electrical surges originate from outside sources, while the other eighty percent originate from equipment in the facility. Small voltage fluctuations can result in catastrophic damage for sensitive electronics.

To protect critical equipment, it’s important to use industrial surge protection. Most industrial facilities use a DIN rail, which is typically used for grounding. When choosing an SPD, look for one that utilizes the benefits of the DIN rail. Generally, the device that uses the DIN rail also benefits from both the mechanical and electrical grounding capabilities. However, if you’re concerned about the safety of your equipment, you can contact a professional electrical engineer for guidance. Get in touch with ZeroDT for industrial surge protector.

The prevalence of electronic equipment in industrial and professional facilities is increasing the need for industrial surge protection worldwide. Microprocessors and programmable logic controls, electronic circuitry, and automation systems are especially vulnerable to power surges. These surges can disrupt processes, cause catastrophic failures, and prematurely age equipment. By protecting your equipment from power surges, you can minimize the likelihood of equipment damage and prevent costly downtime. Ultimately, industrial surge protection allows you to avoid such problems and keep your equipment up and running reliably.

Besides industrial equipment, industrial surge protection is becoming increasingly popular with the adoption of Industry 4.0 initiatives. These initiatives enable remote diagnostics, data capture, and other functions. These technologies require more protection devices and datacenters than ever before. The industrial market is growing due to these factors. You should get industrial surge protectors now. Using industrial surge protection devices helps protect the electronics of critical equipment and decrease repair costs. In addition to industrial applications, the products are also beneficial to consumer electronics.

An industrial surge protection device protects against power surges and transient voltage. Transient voltage (or power surge) is an event that occurs when electrical current levels spike and fall dramatically. Power surges can last for minutes or cycles, depending on the cause. The protection provided by industrial surge protection devices is not sufficient for the duration of these events. It will open internal thermal fuses and activate an overcurrent protection device if the power surge exceeds the threshold, resulting in expensive downtime and equipment damage.

The industrial surge protection devices market is expected to continue to grow in the United States, as more electrical equipment is used in industries like manufacturing. This growth will require increased stability of power supplies in industrial and commercial facilities. Increasing disposable incomes are driving the development of power-quality protection devices, especially in industrial settings. These devices are essential for ensuring safe operations in environments with volatile power quality. In this article, we look at some of the major players in the U.S. market.

Spark-gap semiconductor: These devices are also used as overvoltage clamping devices in high-energy DC circuits. They don’t have as much capacitance as MOV, but they retain their clamping characteristics during surges. The best industrial surge protection devices should protect equipment against multiple types of transient voltage. And if you’re looking for a specific brand, you can choose a thyristor-based device such as Trisil or SIDACtor.