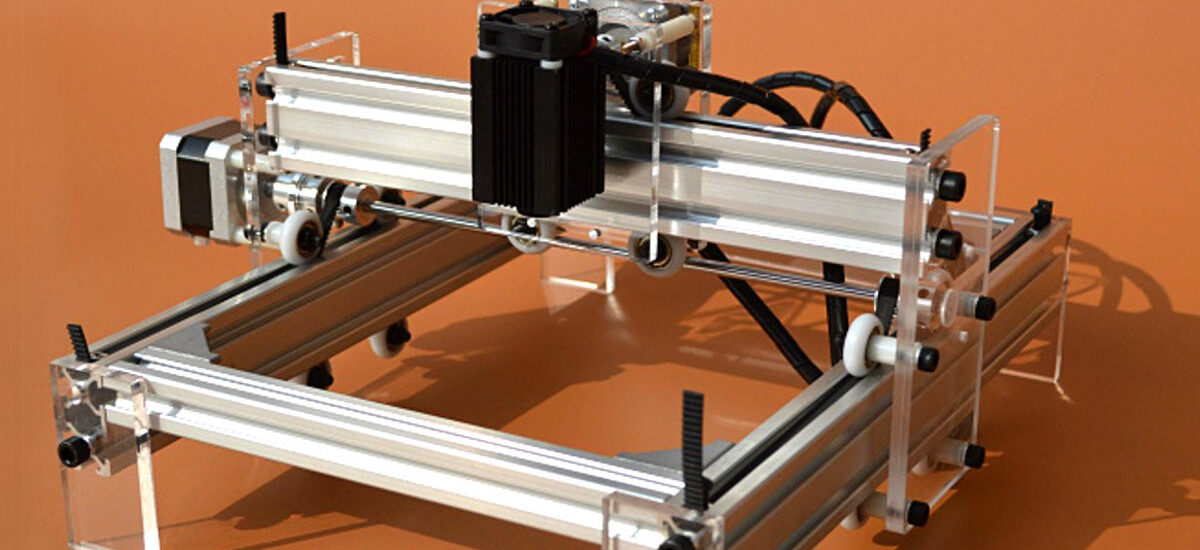

Now, the working principle of laser engraver machine is find within the latest reviews. But in this regard you can also go through the manufacturer’s manual so that necessary details can be gather.

Currently, laser engraving is slowly replacing all kinds of traditional or old techniques especially pad printing and hot stamping and it has been possible due to laser engraver machine. Intricate and precise patterns can be created with this device and thus it is getting used for multiple industrial applications. If you are not aware of the basic fundamentals of this device, then you will not be able to use the same for engraving purposes.

These beams have got higher energy and this energy can create amazing designs by means of engraving materials. Laserowe Znakowanie is suitable for all material types and thus you need not require thinking about material type before starting the task of engraving via laser technology. Resistive masks are need for using laser engraver machine which is the main source for releasing laser beams.

Specific angles need to be maintain for maintaining accuracy and in some cases degrees are calculate. Nowadays, coated materials can also be engraved by these kinds of electronic. The depth can be ascertain by ascertaining the intensity of the materials.

You should plan beforehand that how much depth is required to be engraved for creating your desirable designs and on the basis . The same should start up the task of laser engraving. Make sure that the materials are not getting adversely affected with the laser beams and in this respect the overall quality of the materials.

Laser engraving is a process

Laser engraving is a process that vaporizes materials into fumes to engrave permanent, deep marks. The laser beam acts as a chisel, incising marks by removing layers from the surface of the material. The laser hits localized areas with massive levels of energy to generate the high heat required for vaporization.

Laser engraving vaporizes

Laser engraving is a process that vaporizes materials into fumes to engrave permanent, deep marks. The laser beam acts as a chisel, incising marks by removing layers from the surface of the material. The laser hits localized areas with massive levels of energy to generate the high heat required for vaporization.

To choose the right laser marking process, you should rely on three factors:

- The marking’s resistance: its capacity to remain legible under harsh conditions

- The laser marking speed: the marking time that prevents production bottlenecks

- The material being mark: its compatibility with the marking method

Laser engraving technology is typically use to engrave metal workpieces. That will be expose to various types of wear or surface treatments. Metal engraving works with steel and aluminum (including anodized and die-casting aluminum) Those treatments can include shotblasting, e-coating and heat treatments, addressing the most complex traceability issues.